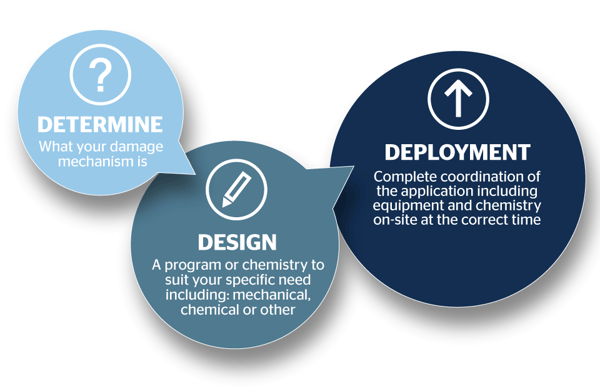

Success starts with understanding.

Enhancing production starts with understanding the situation. First, diagnostics are performed to gain insights to the challenges being faced. From there, we develop a customized program designed to remediate or reduce damage experienced during normal well activities. Our unique Determine, Design, Deploy workflow is the core of our customized solutions. We create significant improvements for wells in many formation types, including Conventional and Thermal operating conditions.

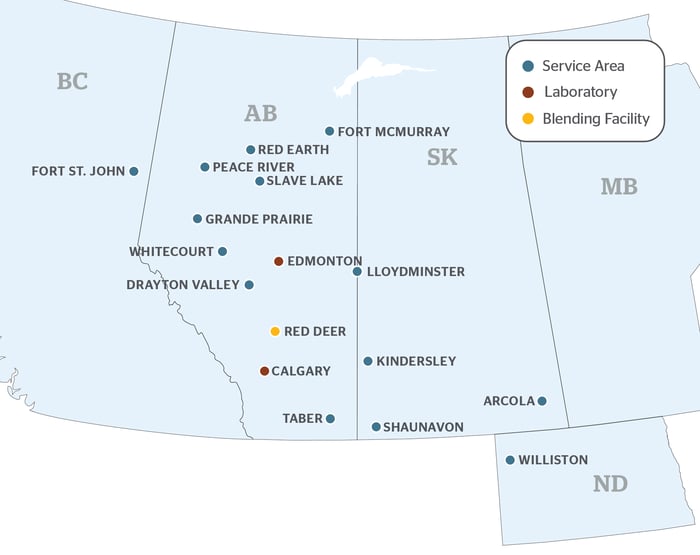

Distribution Advantage

Once we have designed your program, our products and lab testing facilities are easily accessible and ready to deliver, with many locations across Alberta. Our products are locally blended at our Blackfalds blending plant, creating a central distribution point to our warehouses.